Glass-Fiber Reinforced Concrete (GRC)

- Overview

- Data

- Benefit

- Configuration

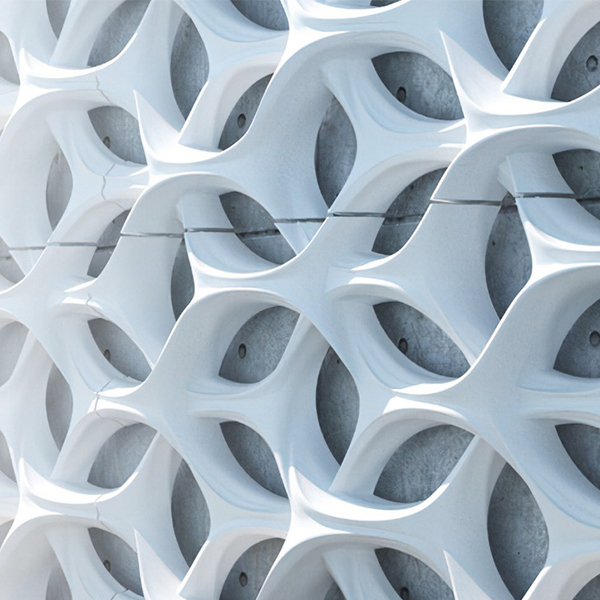

Overview of Glass-Fiber Reinforced Concrete (GRC)

| Product | Glass-Fiber Reinforced Concrete(GRC/GFRC) |

| Material | Alkali Resistant Glass Fiber/Cement/Sand/additive... |

| Surface Treatment | PVDF Coating(Color Customization) |

| Bending Strength | 25Mpa |

| Impact Strength | 10-25KJ/m2 |

| Air-dry density | 1800-2000Kg/m3 |

| Fireproof | Available |

| Standards | In Compliance With ASTM/AS/NZS/AAMA/NFRC/EN/BSI/ISO |

Data of Glass-Fiber Reinforced Concrete (GRC)

Specification Data of Glass-Fiber Reinforced Concrete (GRC)

| Lab Sample ID | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|

| Test Pieces | T1 | T3 | B1 | B3 | T2 | T4 | B2 | B4 |

|

| Orientation of 'mould' face | Down | Up |

|

||||||

| Width (mm) b | 51.2 | 51.2 | 51.3 | 51.6 | 51.5 | 51.4 | 51.2 | 51.3 |

|

| Thickness (mm) d | 11.8 | 10.3 | 10.4 | 11.3 | 10.6 | 10.5 | 10.3 | 10.8 |

|

| Span Length (mm) L | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

|

| Length (mm) | 283 | 281 | 281 | 281 | 280 | 281 | 281 | 281 |

|

| Deflection at LOP (mm) ∆ LOP | 0.333 | 0.439 | 0.442 | 0.365 | 0.474 | 0.437 | 0.378 | 0.386 |

|

| Load at LOP (N) FLOP | 268 | 203 | 235 | 192 | 213 | 182 | 207 | 216 |

|

| Deflection at Failure (mm) ∆ MOR | 11.131 | 10.882 | 10.658 | 8.55 | 9.553 | 10.443 | 10.139 | 8.936 |

|

| Load at Failure (N) FMOR | 651 | 385 | 532 | 616 | 425 | 551 | 511 | 497 |

|

| Wet Mass (g) mw | 370 | 325 | 338 | 367 | 328 | 345 | 338 | 349 |

|

| Dry Mass (g) md | 341 | 298 | 312 | 339 | 302 | 317 | 313 | 322 | MEAN |

| Water Content (%), | 8.35 | 8.88 | 8.4 | 8.32 | 8.79 | 8.73 | 8.12 | 8.32 | 8.49 |

| Deformation at LOP, | 0.0003 | 0.0003 | 0.0003 | 0.0003 | 0.0003 | 0.0003 | 0.0003 | 0.0003 | 0.0003 |

| Stress on LOP (MPa), | 9.4 | 9.34 | 10.59 | 7.29 | 9.2 | 8.03 | 9.53 | 9.02 | 9.05 |

| Deformation at Failure, | 0.0099 | 0.0084 | 0.0083 | 0.0073 | 0.0076 | 0.0082 | 0.0078 | 0.0073 | 0.0081 |

| Stress on Failure (MPa), | 22.83 | 17.72 | 23.97 | 23.37 | 18.36 | 24.31 | 23.52 | 20.76 | 21.86 |

| Relationship of Individual Stresses on Failure |

|

|

|

||||||

| 0.91 | 0.95 | 1.07 | |||||||

| Lab Sample ID | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

|

| Test Pieces | T1 | T3 | B1 | B3 | T2 | T4 | B2 | B4 |

|

| Orientation of 'mould' face | Down | Up |

|

||||||

| Width (mm) b | 51.2 | 51.2 | 51.6 | 51.5 | 51.6 | 51.4 | 51.4 | 50.8 |

|

| Thickness (mm) d | 11 | 11.3 | 11.6 | 11 | 10.9 | 11.8 | 11.2 | 9.9 |

|

| Span Length (mm) L | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

|

| Length (mm) | 281 | 281 | 281 | 281 | 280 | 281 | 281 | 281 |

|

| Deflection at LOP (mm) ∆ LOP | 0.288 | 0.274 | 0.436 | 0.339 | 0.436 | 0.496 | 0.371 | 0.754 |

|

| Load at LOP (N) FLOP | 219 | 196 | 291 | 218 | 293 | 327 | 237 | 236 |

|

| Deflection at Failure (mm) ∆ MOR | 10.296 | 9.476 | 10.991 | 10.543 | 12.492 | 9.101 | 9.837 | 10.472 |

|

| Load at Failure (N) FMOR | 557 | 514 | 538 | 564 | 656 | 680 | 603 | 448 |

|

| Wet Mass (g) mw | 359 | 366 | 366 | 357 | 354 | 375 | 362 | 317 |

|

| Dry Mass (g) md | 329 | 335 | 334 | 326 | 324 | 343 | 331 | 291 | MEAN |

|

|

9.11 | 9.27 | 9.49 | 9.38 | 9 | 9.24 | 9.27 | 8.9 | 9.21 |

|

|

0.0002 | 0.0002 | 0.0004 | 0.0003 | 0.0004 | 0.0004 | 0.0003 | 0.0006 | 0.0004 |

|

|

8.84 | 7.49 | 10.48 | 8.75 | 11.95 | 11.42 | 9.19 | 11.85 | 10 |

|

|

0.0085 | 0.008 | 0.0096 | 0.0087 | 0.0102 | 0.0081 | 0.0083 | 0.0078 | 0.0087 |

|

|

22.48 | 19.66 | 19.37 | 22.63 | 26.75 | 23.75 | 23.38 | 22.49 | 22.56 |

| Relationship of Individual Stresses on Failure |

|

|

|

||||||

| 1.05 | 0.83 | 0.92 | |||||||

| Lab Sample ID | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

|

| Test Pieces | T1 | T3 | B1 | B3 | T2 | T4 | B2 | B4 |

|

| Orientation of 'mould' face | Down | Up |

|

||||||

| Width (mm) b | 51.3 | 51.4 | 51 | 51.3 | 51.3 | 51.5 | 51.6 | 51.4 |

|

| Thickness (mm) d | 11.1 | 10.8 | 10.9 | 11.8 | 10.4 | 11.1 | 11.6 | 10.7 |

|

| Span Length (mm) L | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

|

| Length (mm) | 281 | 281 | 281 | 281 | 280 | 281 | 281 | 281 |

|

| Deflection at LOP (mm) ∆ LOP | 0.349 | 0.312 | 0.335 | 0.332 | 0.488 | 0.371 | 0.46 | 0.403 |

|

| Load at LOP (N) FLOP | 247 | 206 | 243 | 249 | 246 | 233 | 244 | 220 |

|

| Deflection at Failure (mm) ∆ MOR | 10.443 | 10.514 | 8.582 | 12.102 | 9.035 | 9.653 | 8.59 | 11.947 |

|

| Load at Failure (N) FMOR | 629 | 551 | 524 | 682 | 580 | 566 | 643 | 552 |

|

| Wet Mass (g) mw | 367 | 351 | 360 | 371 | 354 | 345 | 372 | 342 |

|

| Dry Mass (g) md | 337 | 323 | 331 | 341 | 328 | 318 | 343 | 314 | MEAN |

| Water Content (%), | 9 | 8.66 | 8.74 | 8.74 | 8.93 | 8.6 | 8.54 | 8.88 | 8.76 |

| Deformation at LOP, | 0.0003 | 0.0003 | 0.0003 | 0.0003 | 0.0004 | 0.0003 | 0.0004 | 0.0003 | 0.0003 |

| Stress on LOP (MPa), | 9.77 | 8.59 | 10.03 | 8.71 | 11.08 | 9.18 | 8.79 | 9.35 | 9.44 |

| Deformation at Failure, | 0.0087 | 0.0085 | 0.007 | 0.0107 | 0.0071 | 0.0081 | 0.0075 | 0.0096 | 0.0084 |

| Stress on Failure (MPa), | 24.88 | 22.98 | 21.62 | 23.87 | 26.13 | 22.3 | 23.15 | 23.45 | 23.55 |

| Relationship of Individual Stresses on Failure |

|

|

|

||||||

| 1.05 | 0.99 | 0.98 | |||||||

| Non-combustibility Test: |

|

|

|

|

|

||||

| Lab. Sample I.D. | FU90030/1 | FU90030/2 | FU90030/3 | Specification of non-combustibility on BS 476:part 4:1970 CI.8 | |||||

| Time of flame continuously (s) | 0 | 0 | 0 | ≤10 | |||||

| The temperature rise of the furnace above the initial furnace temperature (℃) | 0 | 0 | 1 | ≤50 | |||||

| The temperature rise of specimen centre above initial furnace temperature(℃) | 0 | 0 | 0 | ≤50 | |||||

| Compressive Strength Test: | |||||||||

| Lab. Sample I.D. | Width(mm) | Thickness(mm) | Maximum Force(N) | Compressive Strength(N/mm2) | |||||

| ST150319/4 | 9.61 | 74.75 | 14055.00 | 19.55 | |||||

| ST150319/5 | 10.50 | 76.02 | 15480.00 | 19.40 | |||||

| ST150319/7 | 10.31 | 74.62 | 15480.00 | 20.13 | |||||

| ST150319/8 | 10.26 | 75.03 | 15460.00 | 20.09 | |||||

| ST150319/9 | 10.06 | 74.28 | 14310.00 | 19.14 | |||||

| Average | 10.15 | 74.94 | 14957.00 | 19.66 | |||||

Benefit of Glass-Fiber Reinforced Concrete (GRC)

-

Infinite plasticity

-

Lightweight & high strength

-

Thin thickness & large size

-

Rich in colors and shapes

-

Various textures and surface treatments

-

Environmental protection & no radiation

-

Fire prevention and waterproof

-

Stain-resistant, no deformation, super durability

-

Good sound insulation and earthquake resistance

-

Short construction period, convenient maintenance, easy to replace